Current location:Home > hydraulic cylinder wiper seal >

hydraulic cylinder wiper seal

2025-08-14 05:19

2025-08-14 05:09

2025-08-14 04:45

2025-08-14 04:43

2025-08-14 04:35

2025-08-14 04:27

2025-08-14 04:08

2025-08-14 03:50

2025-08-14 03:50

2025-08-14 03:39

Latest articles

Materials play a critical role in the performance of high pressure shaft seals. It is important to select materials that are compatible with the fluids being sealed and can withstand the high pressures and temperatures that may be present. Common materials used for high pressure seals include rubber, plastics, and metals, each with their own advantages and limitations. For example, rubber seals are flexible and provide good sealing performance, but may wear out quickly under high pressure conditions. On the other hand, metal seals are more durable but may not provide as tight a seal

high pressure shaft seals.

high pressure shaft seals.

One of the key challenges in high-speed rotary shaft seals is managing heat generation. The friction caused by the seal's contact with the shaft can lead to significant heat build-up, potentially affecting the seal's integrity and lifespan. To combat this, advanced materials and designs, such as thermally conductive fillers, are employed to dissipate heat efficiently To combat this, advanced materials and designs, such as thermally conductive fillers, are employed to dissipate heat efficiently To combat this, advanced materials and designs, such as thermally conductive fillers, are employed to dissipate heat efficiently To combat this, advanced materials and designs, such as thermally conductive fillers, are employed to dissipate heat efficiently

To combat this, advanced materials and designs, such as thermally conductive fillers, are employed to dissipate heat efficiently To combat this, advanced materials and designs, such as thermally conductive fillers, are employed to dissipate heat efficiently high speed rotary shaft seals.

high speed rotary shaft seals.

To combat this, advanced materials and designs, such as thermally conductive fillers, are employed to dissipate heat efficiently To combat this, advanced materials and designs, such as thermally conductive fillers, are employed to dissipate heat efficiently

To combat this, advanced materials and designs, such as thermally conductive fillers, are employed to dissipate heat efficiently To combat this, advanced materials and designs, such as thermally conductive fillers, are employed to dissipate heat efficiently high speed rotary shaft seals.

high speed rotary shaft seals.2. Design Specifications The unique design aspects, such as the sealing lip geometry and the hardness of the rubber, are optimized to balance flexibility and resilience. This design ensures proper contact with the shaft, reducing the risk of oil leakage and improving the overall efficiency of the machinery.

25 35 7 oil seal

Another advantage of the single lip oil seal is its ability to withstand harsh operating conditions single lip oil seal. The materials used to manufacture these seals are resistant to heat, chemicals, and other environmental factors that can degrade traditional sealing solutions. This makes them an ideal choice for applications where the environment is particularly challenging.

single lip oil seal. The materials used to manufacture these seals are resistant to heat, chemicals, and other environmental factors that can degrade traditional sealing solutions. This makes them an ideal choice for applications where the environment is particularly challenging.

single lip oil seal. The materials used to manufacture these seals are resistant to heat, chemicals, and other environmental factors that can degrade traditional sealing solutions. This makes them an ideal choice for applications where the environment is particularly challenging.

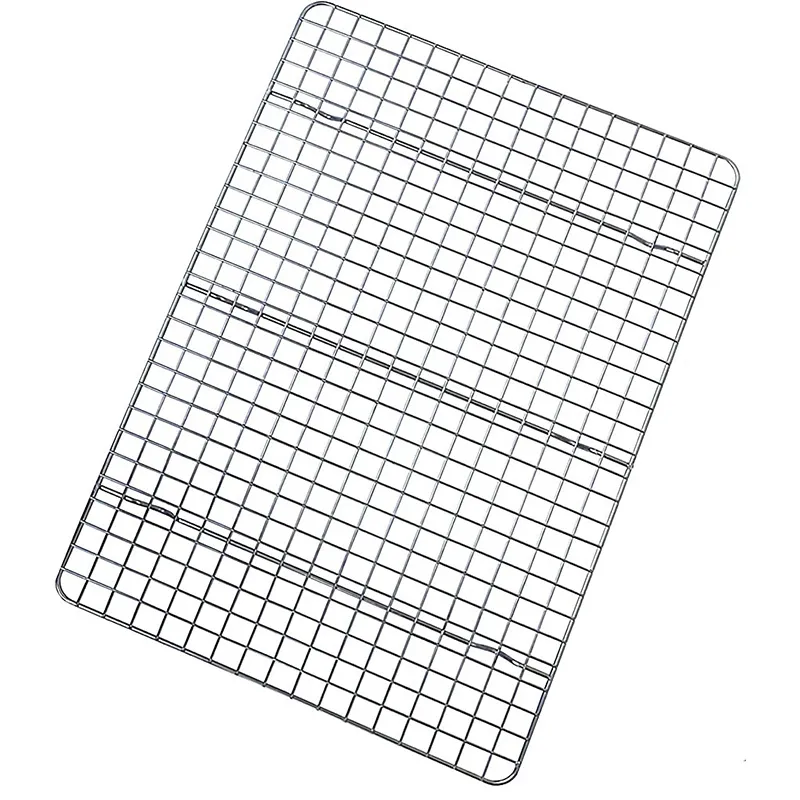

single lip oil seal. The materials used to manufacture these seals are resistant to heat, chemicals, and other environmental factors that can degrade traditional sealing solutions. This makes them an ideal choice for applications where the environment is particularly challenging.Aside from improving texture, using wire racks for cooling also enhances the flavor of baked goods. Cooling on a wire rack prevents the build-up of moisture, which can dilute the flavors you’ve painstakingly developed during the baking process. When baked items dry out just the right amount, their flavors intensify, giving each bite a satisfying, well-rounded taste.

wire rack for cooling